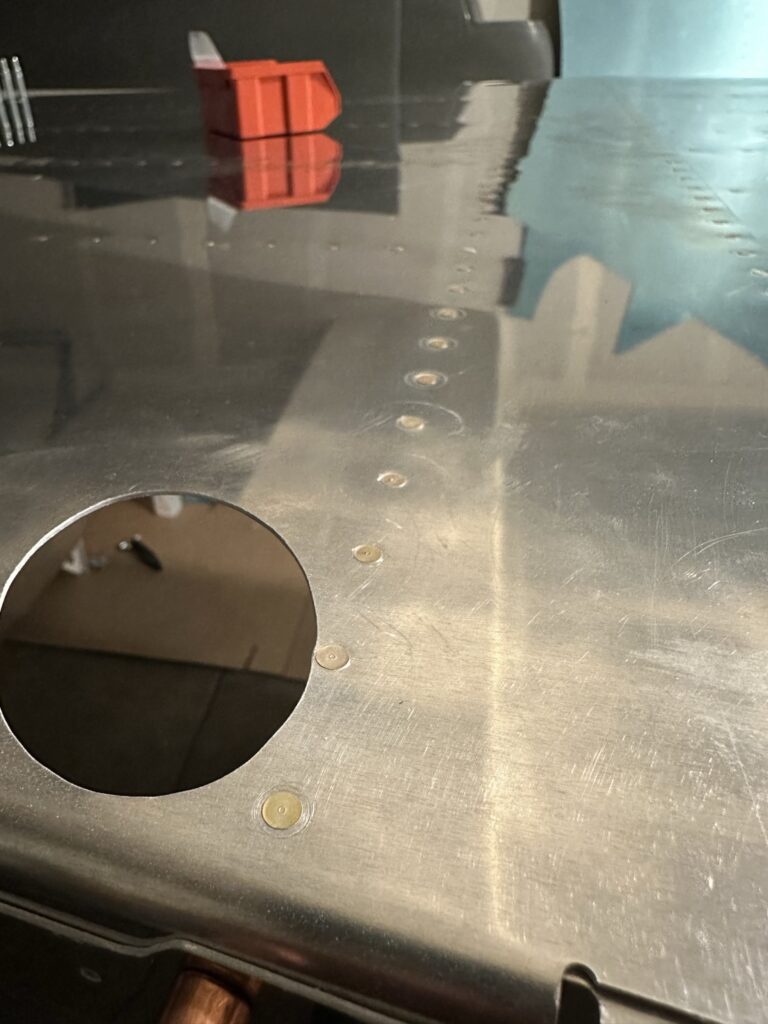

This hole in the bottom of the fuse drove me nuts. It’s incredibly close to a rivet (edge-distance aside, I’m nearly shaving the factory head of this rivet!), a very specific shape and position, and generally just a harrowing ordeal to modify this skin in such a manner.

I’ve viewed at least a half-dozen other builds to make sure this is done right, and from what I can find is most everyone is doing the same thing as me: triple checking they don’t mess this up.

The number one mistake seems to be not ensuring the weldment fits, and just going from the template and calling it good. Then, later in the build, folks have to adjust–and it’s much harder to adjust at that point.

The template is about as good as a paper template can be. Have to give some credit to the plans here. It does require minor (1/16″) adjustment in certain areas to get the weldment to fit. There’s a fairing, so you could error on the side of too big and no one would be the wiser once the fiberglass was on, however that rivet makes it hard to error on the side of too big. Not to mention you instinctively want to remove as little of the spar flange as possible.

In the end, it looks nice and fits the weldment very closely. I’m happy here, but the true test won’t come until I bolt that weldment in place…