Gluing the windscreen on the airplane was nerve-wracking. Sika Flex was again the weapon of choice, and even though I’m feeling more confident with the Sika Flex system, it’s still a messy and permanent approach to windscreen and canopy attachment.

The important part was getting both clamping and spacing worked out. Spacing was required to ensure the windshield would mate well with the canopy. Clamping was required to ensure the windscreen was sitting firmly on the spacers.

Spacers came in the form of “chunks” of tubing stuck with VHB tape that would be fully encapsulated in Sika, never to be seen or removed.

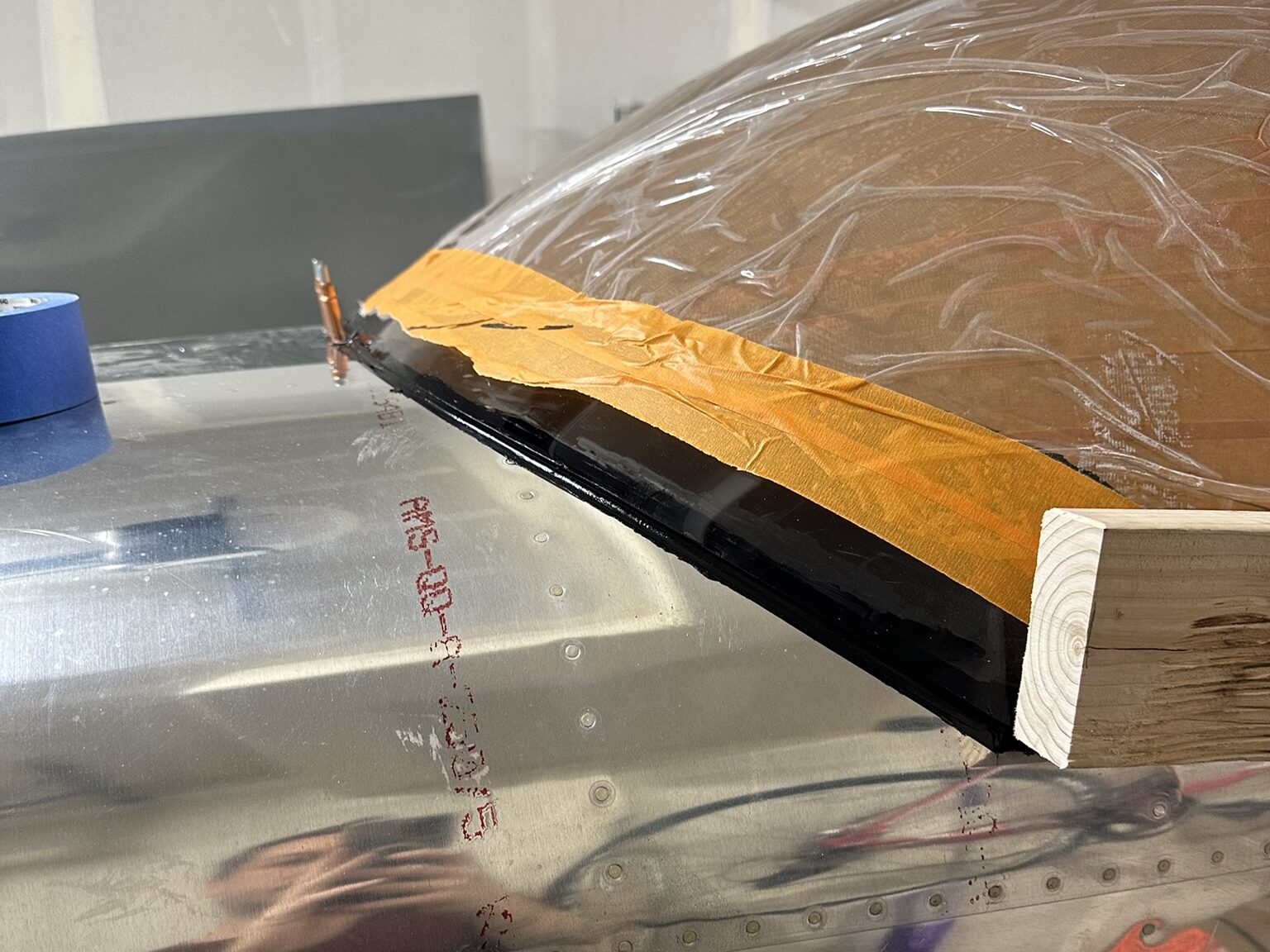

Clamps, I wish, would have take a bit more graceful form, but wound up doing the job.

Welding clamps and wooden blocks ensured the sides of the canopy would now bow out. These were likely the most critical clamps in the entire operation.