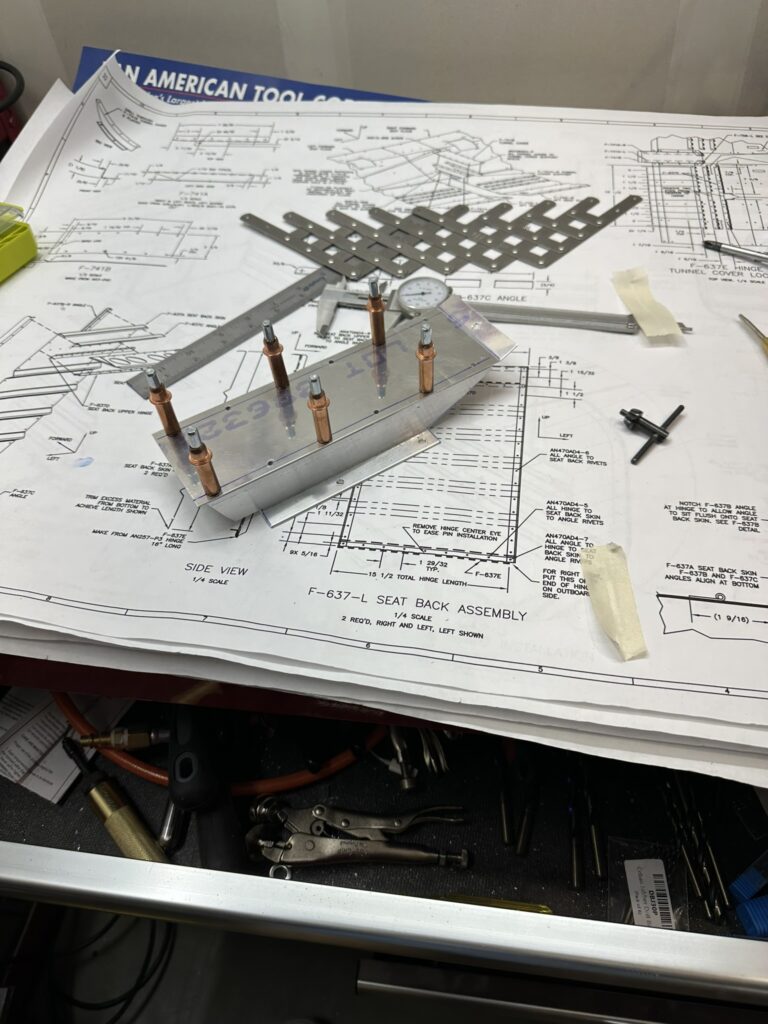

The tunnel cover was largely fabricated with the seat bottoms. The two pieces of Z-extrusion were cut to the specified dimensions, including several angled jogs (one is about 1/16″ off, and I think I’ll redo it–it bugs me that much).

The bottom holes were carefully drilled by extending lines out (on tape, not the white paint) from the centerline of each forward nutplate on tunnel. I wanted to make sure these lined up, and without the ability to match drill it is a little tough.

The top seems to be designed with some extra length in mind. I say this because the plans say to match drill the top when all is in place and the front angle fits. If I do this, I have about 3/16″ sticking off the back end. This worries me, but not overly as I’ve seen it mentioned before.

Once everything is drilled I’m setting this aside. I don’t feel like priming it yet when this top piece might need to be altered or replaced, and I may replace one of the rails. Worst case scenario, 2/3 of the thing is getting redone.