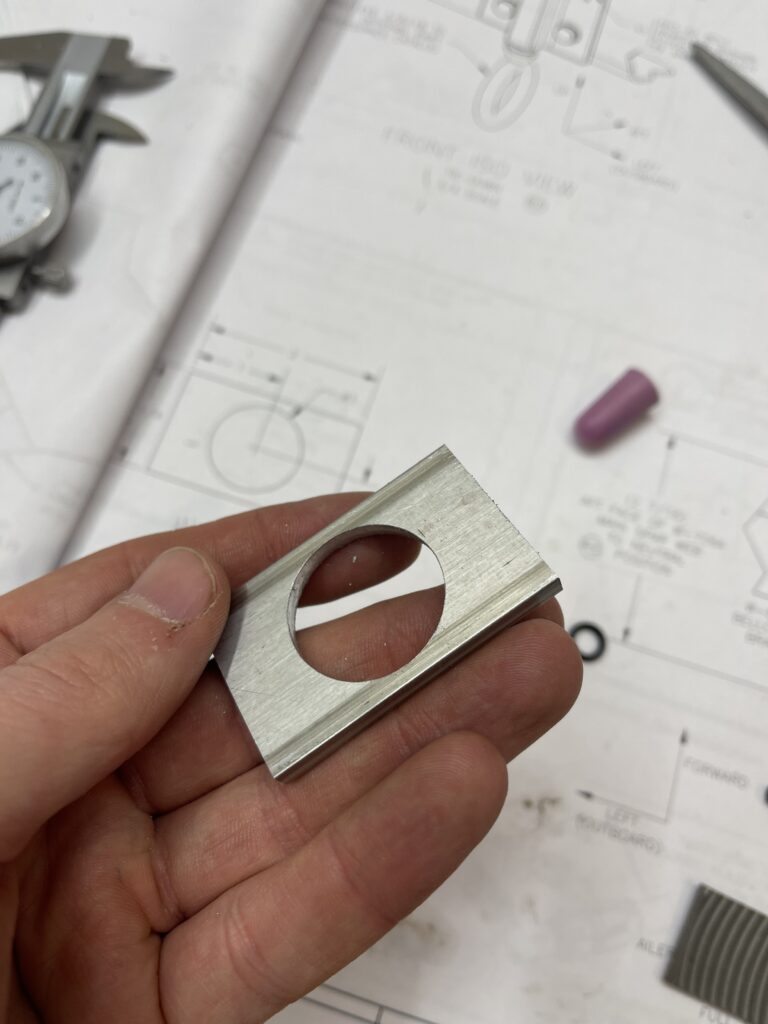

After the spar was working on the wing tiedown hardware. Among the first things to do was to fabricate some spacers. The 1″ holes proved difficult to drill, and took a few trips to different hardware stores. The HF circle cutter is useless. Two different hole saws wouldn’t provide the clean cuts I wanted. Finally, a nicer circle cutter found at Ace did the trick.

Some helpful tips I learned. Cutter needs to be a low speed. This should be obvious, but maybe not if you haven’t used one of these. Pay attention to the RPM suggestions on the package. I used cutting oil. I went halfway through, flipped the piece and did the other half. This works great.

I cut the 2″ lengths first. In hindsight, they would have been easier to cut on the parent strip, then cut apart. Space between each would be needed for the kerf of the blade.

Next up is tapping the extrusion and drilling holes.