Many builders have asked about the tools I have utilized for my wiring and avionics—in specific, my crimpers and positioners. This is a look at everything connectors.

First, some background and definitions: The crimpers we’re working with here have four points that indent a barrel type terminal on the end of a wire. Typically you insert some sort of terminal, set your crimp depth, insure wire is inserted into the terminal, and crimp.

The terminals have hundreds—nay, thousands of variations, but the main ones we’re using are Garmin dsub pins and barrels as well as size 16 Deutsch pins and barrels. All these terminals accept a different span of wire gauge, require a slightly different amount of stripped wire end, and require different amounts of crimping. It’s usually here where the confusion sets in. Hold the questions for now, we’re moving forward.

Positioners. Positioners are nothing more than a steady set of hands. They do exactly as their name implies: they position the terminal within the housing of the crimper such that the crimp will land on the correct spot on the barrel. They also hold the terminal centered within the crimper so that your crimp points land concentrically around the barrel, and the barrel doesn’t get jammed up in the crimper. Why, then, so many weird item numbers, SKUs, milspec variations, and so forth? Because aviation.

Daniels is likely the most well-known name in avionics. Avionics crimping tools that is. The DMC crimper is ubiquitous in avionics shops at every airfield. But with it’s $500+ price tag, it leaves many amateurs looking for a runner up.

JRready fills that spot with its line of crimpers, positioners, and—to boot—has a line of other products that are in the periphery of avionics wiring. Their full line of Deutsch connectors can pick up where your Garmin or Dynon connectors left off.

Here’s a rundown of the products needed to wire your plane from a perspective of connectors, terminals, and related pieces.

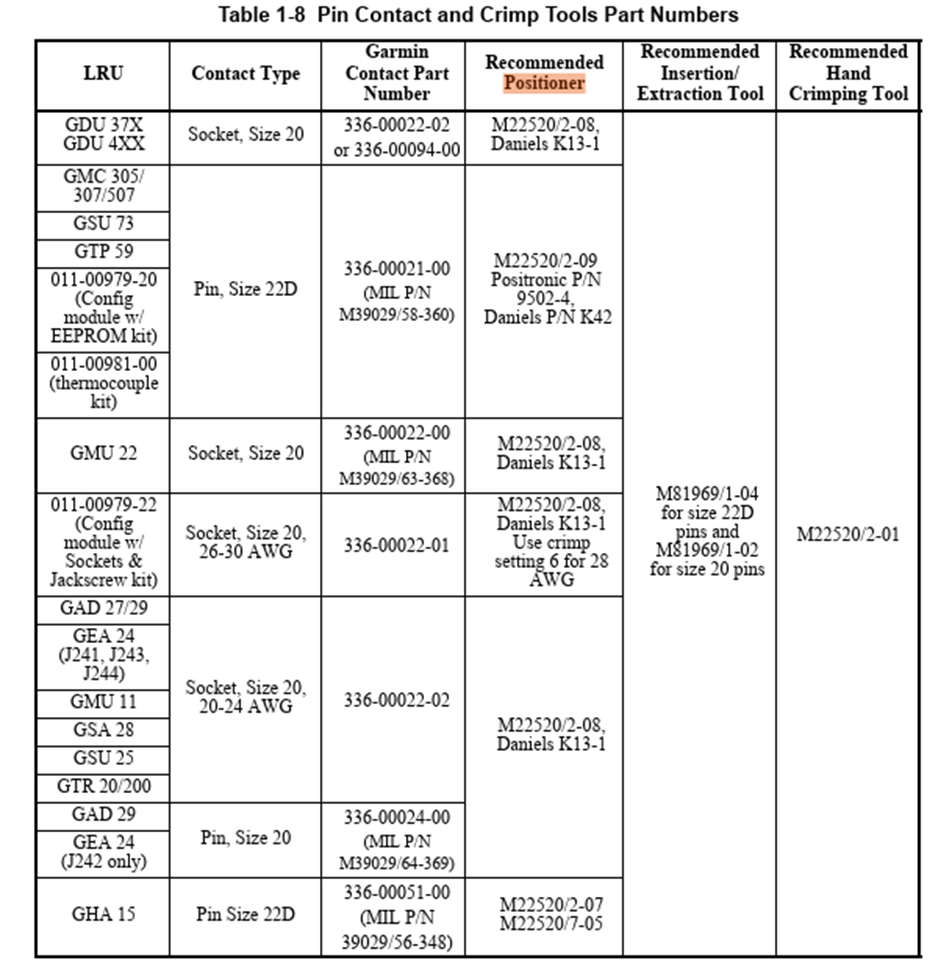

First, the coherence of the JRready product catalog is tenuous. It’s a product marketing manager’s worst nightmare; a smattering of partially-related products with varied compatibility and virtually no navigability. So instead of starting there, we’re going to start with what’s required of your crimper via the Garmin installation manual:

(Table 1-8 from the G3X installation manual)

This table outlines the connectors used for each LRU and its respective connectors. For DMC users, it’s easy to identify that most LRUs are going to use either the K13-1 or the K42. At this point it is probably tempting to try and start converting Daniels to JRReady part numbers, starting out by looking at the K Series positioners.

Don’t.

I have myriad unused positioners by falling victim to this. It’s far easier than that. JRReady positioners, aside from their K and P markings, also have indicators on the milspec number that they’re useful for. And in this lexicon, we’re looking for M22520/2-08 and M22520/2-09 for the vast majority of what we’re crimping here. It’s that easy.

And you’re going to find these item numbers on the P208 and P209 positioners:

Now, you set your sites on a suitable milspec crimper from JRready. The two main crimpers are going to be your AS2 and AS2G. Both of these have compatibility with 20 – 32 AWG wiring, can utilize a host of positioners, and are readily available. The differences? Not sure. Size, maybe?

Regardless, the crimper/positioner combo will get you through most of the crimping needed for avionics.

What’s left? Well, honestly most of the things outside of avionics. You see, 20 AWG doesn’t leave a lot of headroom for items like lighting, trim, flaps, and certainly pitot heat. All these systems are run using some 20, but a lot of 16-18 AWG wire. They’re also running through (per your recommendation, Ryan!) Deustch DT connectors, with size 16 terminals that accept 16 – 20 AWG wire. That means that our Venn diagram of available wires running from avionics through separate connectors has one wire guage that works: 20AWG.

Ok, ok, so there’s flaws in the system here. First off, I’ve been known to crimp an 18 AWG wire in a JRready crimper, a size 16 terminal, with a manual positioner. A lot. It works. Might these fail prematurely? Time will ultimately tell, but inspection shows no cracking of the terminal, and a pull test doesn’t show any noticeable weakening of the wire.

Similarly, a 22AWG wire (most avionics components) will work in a Deutsch connector with a size 16 terminal—tug-test certified. Might these two outside cases be frowned upon? Probably, but if you’re reading this than you too have noticed what a struggle it is just to figure out what connectors and wires to use for your project—a landscape littered with dead ends and false starts. From my testing, inspections, and reviews, I think it’s a solid system.

So, that’ll get you through 90% of your plane. The rest? Well, I’m still figuring that out. I have 14 AWG wire heading to my pitot heat. The original intent was to use Deutsch DTP connectors (size 12 terminals, good for 12 – 16 AWG wire with a current rating of 25 amps, continuous), but finding a suitable crimper without spending $300 has been difficult. A set of $35 crimpers from Amazon has proved to work suitably, but not ideal.

I will note, here, that there is a better breed of terminals available out of Deutsch Connector Store, at deutschconnectorstore.com. For one, they have milspec terminals available, for those that are set on having that.

For those that don’t need milspec, and are ok with (still gold plated) standard solid terminals, they have some options that are interesting. For one, a 14AWG terminal that could eliminate the need for a DTP connector on something like pitot heat. However, without an updated current rating, I’m inclined to believe these are still limited to the 13amp cited elsewhere for size 16 connectors, so it might not get you as far as you had hoped.